Quick Answer: A water heater expansion tank protects your plumbing system from thermal expansion by absorbing excess pressure when heated water expands in a closed plumbing system. Without it, pressure buildup can trigger leaking T&P valves, pipe damage, premature water heater failure, and other costly issues.

Understanding the Water Heater Expansion Tank: The Complete Technical Breakdown

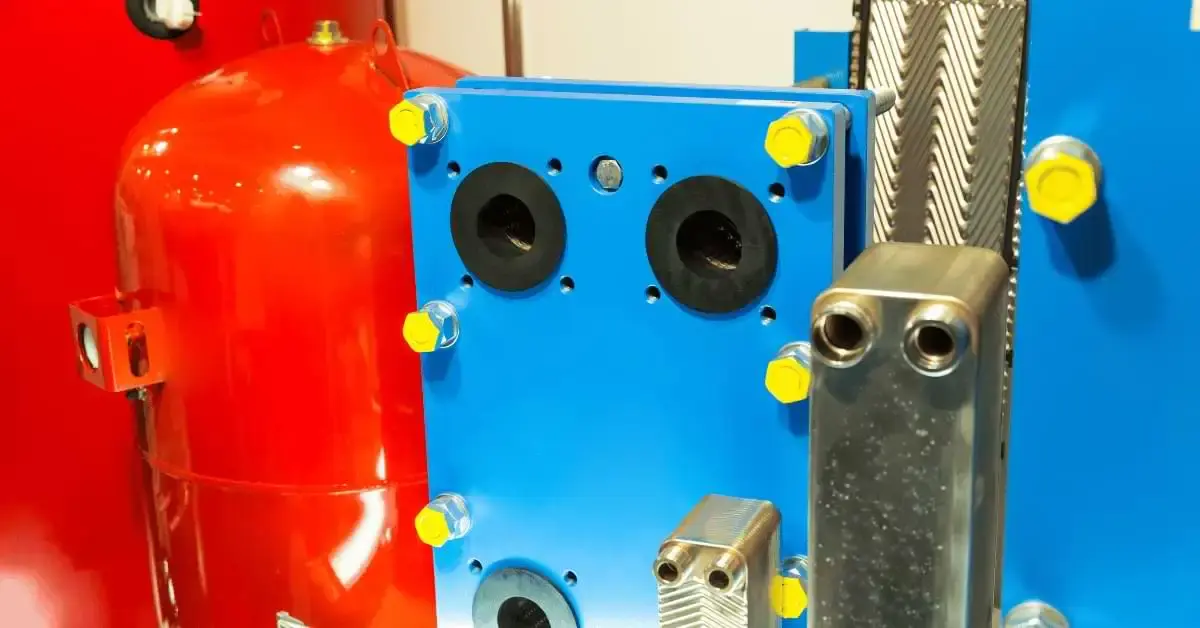

A water heater expansion tank is a small hydropneumatic tank installed on the cold water supply line to absorb pressure caused by thermal expansion. Anytime water is heated, it expands, and because water is incompressible, pressure rises rapidly inside a closed plumbing system.

Modern homes often have a backflow prevention device, check valve, or pressure reducing valve (PRV) that prevents this expanding water from flowing backward into the city main. This creates a closed system where expanded water has nowhere to go.

This is exactly where the bladder tank, also called a diaphragm expansion tank, does its job.

Inside the tank, a rubber diaphragm separates water from an air cushion. As expanding water enters the tank, the air compresses and absorbs the excess force, preventing pressure spikes, fluctuating water pressure, and relief valve discharge.

What Is a Water Heater Expansion Tank and What Does It Do?

A water heater expansion tank is a safety device that provides an additional chamber for expanded water, preventing excessive pressure in the plumbing system.

Its goals include:

- Stabilizing static water pressure

- Protecting the Temperature and Pressure Relief Valve (T&P valve)

- Reducing stress on plumbing fixtures

- Preventing burst pipes, leaks, and tank deformation

- Extending overall water heater life

Many homeowners first contact a Local Plumber after noticing water hammer, dripping T&P valves, or knocking pipes — all symptoms tied directly to uncontrolled thermal expansion.

Why Expansion Tanks Are Required in Many Homes

Most plumbing codes now require expansion tanks whenever a water heater is installed on a closed system. Homes with:

- A PRV

- A check valve

- A whole-house backflow device

are all classified as closed systems under modern plumbing codes.

This makes an expansion tank not just beneficial, but essential for preventing damage.

How an Expansion Tank Works (Technical Explanation)

To fully understand how an expansion tank works, you need to know its internal pressure mechanism:

- The tank is pre-charged with air at a specific pre-charge pressure.

- This pressure matches the home’s static water pressure.

- When the water heater activates, expanded water pushes against the diaphragm.

- The air bladder compresses and absorbs the additional force.

- Pressure remains stable throughout the system.

This controlled compression prevents:

- T&P valve leaks

- Excess wear on fixtures

- Damage to the hot water heater itself

- Repeated running of toilets or dripping faucets

Correct Size of a Water Heater Expansion Tank

Choosing the wrong size is one of the top causes of a waterlogged expansion tank, failed diaphragm, or inconsistent pressure.

Below is a reference based on typical conditions:

Expansion Tank Sizing Chart

| Water Heater Capacity (Gallons) | Recommended Expansion Tank Size | Notes |

|---|---|---|

| 30–40 gallons | 2-gallon tank | Standard homes |

| 40–50 gallons | 3–4.5 gallon tank | Most common installation |

| 50–80 gallons | 5-gallon tank | Larger households |

| 80–120 gallons | 6-10 gallon tank | High-demand systems |

Where the Expansion Tank Should Be Installed

While many configurations exist, experts prefer installation on the cold water supply line above the water heater. The installation of an expansion tank will also resolve the issue if hot water runs out fast in winter.

This ensures that:

- The tank captures thermal expansion immediately

- Pressure remains stable before water circulates

- The diaphragm tank lasts longer due to cooler water exposure

A mounting bracket or support strap may be required depending on weight, orientation, and pipe type.

Horizontal vs. Vertical Installation

Both are acceptable if done correctly:

- Vertical installation is preferred for longevity.

- Horizontal installation requires proper support to avoid stress on pipe fittings.

Many mistakes traced back to DIY installations come from ignoring cold inlet line placement and improper pipe fittings and dielectric unions.

Symptoms of a Failing Water Heater Expansion Tank

A failing expansion tank can trigger widespread plumbing issues. These are the most reliable diagnostics:

- Leaking T&P valve

- Toilet flushing on its own or dripping faucets

- High nighttime water pressure

- Water hammer / knocking pipes

- Relief valve discharge

- Mineral buildup around fittings

- Fluctuating water pressure

- Premature water heater failure

If ignored, the failed air cushion leads to a waterlogged expansion tank, which can’t absorb pressure at all.

Quick Fixes You Can Try Immediately

Here are simple steps homeowners can take:

- Tap the expansion tank — if it sounds full of water, the bladder may be ruptured.

- Check the T&P valve — constant dripping signals uncontrolled pressure.

- Confirm pre-charge pressure — it must match static water pressure for proper operation.

If these steps reveal a deeper issue, contacting a Water heater repair specialist ensures safe testing and replacement.

Detailed Warning Signs That Require Immediate Attention

1. Failed or ruptured bladder

This eliminates the air cushion and turns the tank into a solid water-filled chamber. Pressure rises instantly during heating cycles.

2. Relief valve discharge

Even small bursts are indicators that the tank volume or pre-charge pressure is mismatched.

3. Burst pipes

Extreme pressure spikes can rupture copper, CPVC, or PEX lines — especially in older homes.

4. Backflow issues

A stuck check valve combined with thermal expansion is one of the leading causes of line failures.

Proper Expansion Tank Installation Process

- Measure static water pressure using a pressure gauge.

- Match the pre-charge pressure to the meter reading.

- Verify the expansion factor based on water heater temperature.

- Use proper pipe fittings and supports.

- Follow local plumbing code requirements.

Common Problems and Their Causes

| Symptom | Likely Cause | Related Entity |

|---|---|---|

| Dripping T&P valve | High pressure | Pressure buildup |

| Loud banging pipes | Water hammer | Pressure spikes |

| Low hot water output | Tank damage | Premature water heater failure |

| No pressure relief | Blocked valve | Backflow prevention device |

| Constant water heater replacement | Overpressure | Hydropneumatic tank failure |

Pro Tips to Extend Expansion Tank Life

- Check the pre-charge pressure every 6–12 months.

- Inspect the diaphragm tank for exterior rust or corrosion.

- Ensure the mounting bracket is solid and supports full tank weight.

- Replace the tank every 5–10 years depending on water quality.

Call Camco Rooter for Expert Expansion Tank Service

Hot water pressure problems can escalate quickly, from dripping valves to full system failures. A professional inspection ensures correct sizing, proper pre-charge pressure, and code-compliant installation.

If you’re noticing pressure fluctuations, valve discharge, or water hammer, the experts at Camco Rooter can diagnose and repair the issue fast.

Call (562) 373-4445 for same-day expansion tank service and water heater protection.

Frequently Asked Questions About Water Heater Tank Expansion Guide

How do I know if my expansion tank is working?

Lightly tap the tank: the top should sound hollow (air cushion), and the bottom should sound full (water). If the entire tank sounds solid, the bladder may have failed.

Can an expansion tank be too big?

Yes. Oversized tanks reduce efficiency and may cause inconsistent pressure absorption, though they rarely cause system damage.

How often should a water heater expansion tank be replaced?

Most last 5–10 years, depending on water pressure, mineral content, and whether the pre-charge pressure is maintained properly.

Does an expansion tank prevent water hammer?

It helps reduce pressure spikes, but severe water hammer may require additional devices such as water hammer arrestors.

What happens if I don’t install an expansion tank on a closed system?

Expect pressure-related problems including dripping T&P valves, pipe stress, fixture leaks, and accelerated water heater wear.